As an efficient and environmentally friendly construction production method, the wall sandwich panel roll forming machine is gradually becoming an important part of the modern construction industry. Through automation and mechanization, the production line improves production efficiency, reduces production costs, and brings unprecedented development opportunities to the construction industry

View more

The corrugated aluminum alloy grille wall panels produced by this roll forming machine hold a significant position in the field of architectural decoration due to their unique charm and practicality. Made from high-quality aluminum alloy, these panels are not only lightweight but also durable, providing an excellent solution for modern architecture.

View more

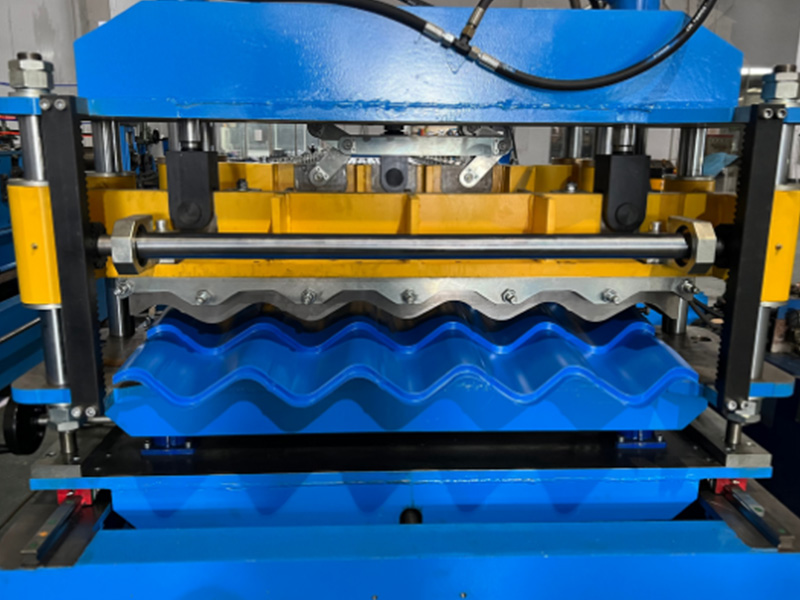

The double layer roofing sheet roll forming machine combines the functions of two models into one dual-purpose device. It features a new double-layer design, enabling switching between high and low frames. It can simultaneously produce two types of color steel tiles, with high production efficiency, compact size, and easy transportation.

View more

The color steel tiles produced by this roll forming machine are a common building material widely used in various construction projects due to their excellent durability, aesthetic appeal, and cost-effectiveness.

View more

Metal glazed tiles are produced by roll forming machines and are primarily composed of metal materials and a glazed coating. They feature advantages such as being lightweight, high-strength, corrosion-resistant, waterproof, and fireproof, making them widely used in roofing, walls, and other construction fields.

View more

The standing seam machine adopts fully automated production. Its products are favored in the construction industry for their stability and aesthetic appeal, widely used for roofs, walls, and other applications.

View more

Our high-quality gutter making machine can produce round gutters, square gutters, trough gutters, gutter covers, or provide roll forming solutions based on your profile drawings.

View more

Our company offers various models of downspout machine with higher productivity, lower costs, and competitive pricing. Using our machines will make your gutter downspout more competitive in the market.

View more

Light steel framing machines are characterized by low power consumption, low noise, low pollution, high efficiency, and highly flexible production. Additionally, roll forming equipment offers unparalleled advantages over traditional presses in manufacturing, transportation, and installation.

View more

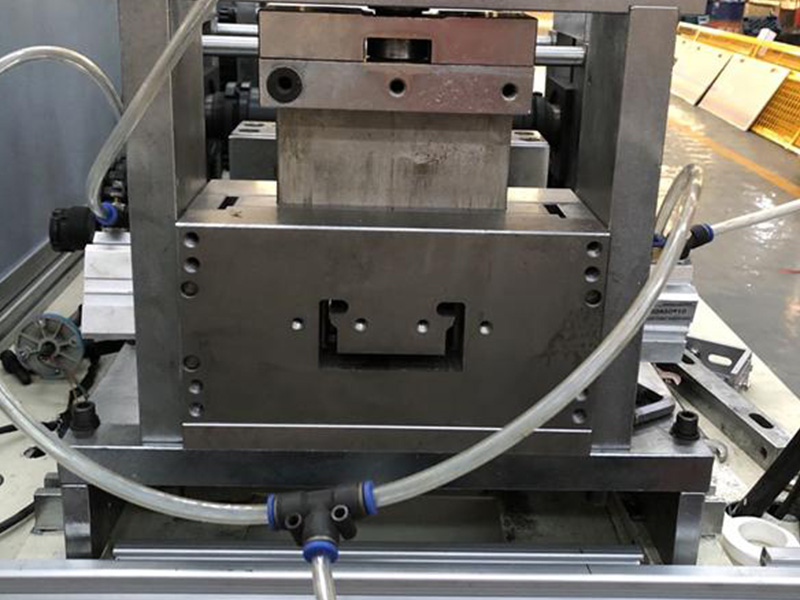

A drywall roll forming machine is a cold bending mechanical device used to produce "partition keels." The products are mainly used in the keel structures of indoor building renovations for factories, office buildings, offices, large and medium-sized shopping centers, retail stores, and supermarkets.

View more

The fully automatic c&z purlin forming machine can produce various specifications of C/Z purlins using a single set of equipment through simple automatic or manual stepless adjustments. There is no need to replace forming rollers when changing specifications. The production process adopts an automatic control system, allowing for automatic punching, cutting, and forming based on the input parameters such as purlin length, longitudinal hole spacing, and quantity.

View more

The metal decking produced by the metal deck roll forming machine has the advantages of light weight, high strength, large stiffness, convenient and fast construction, easy to update, and suitability for industrialized production.

View more