Light steel framing machines are characterized by low power consumption, low noise, low pollution, high efficiency, and highly flexible production. Additionally, roll forming equipment offers unparalleled advantages over traditional presses in manufacturing, transportation, and installation.

View more

A drywall roll forming machine is a cold bending mechanical device used to produce "partition keels." The products are mainly used in the keel structures of indoor building renovations for factories, office buildings, offices, large and medium-sized shopping centers, retail stores, and supermarkets.

View more

The fully automatic c&z purlin forming machine can produce various specifications of C/Z purlins using a single set of equipment through simple automatic or manual stepless adjustments. There is no need to replace forming rollers when changing specifications. The production process adopts an automatic control system, allowing for automatic punching, cutting, and forming based on the input parameters such as purlin length, longitudinal hole spacing, and quantity.

View more

The metal decking produced by the metal deck roll forming machine has the advantages of light weight, high strength, large stiffness, convenient and fast construction, easy to update, and suitability for industrialized production.

View more

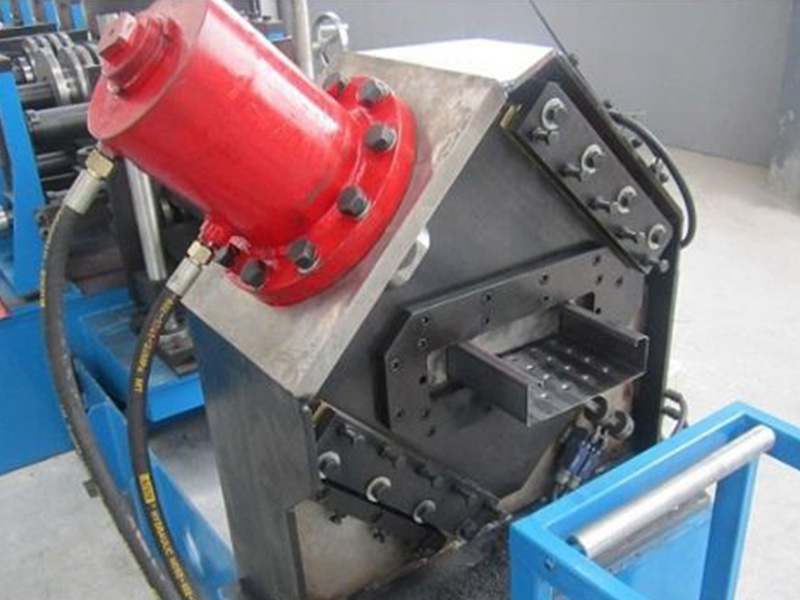

The shipping container bottom beam forming machine is a container equipment designed for the bottom beams of sea freight containers, suitable for various applications such as automotive chassis manufacturing. The high-powered motor and welded H-beam frame ensure its high efficiency and durability. This equipment uses a hydraulic cutting method, ensuring that the produced bottom beams have precise dimensions and quality.

View more

Scaffolding steel planks roll forming machine produces platform pedals, which are one of the most common types of scaffolding pedals. They are usually made of metal plates and have features such as strength, durability, and slip resistance.

View more

The solar photovoltaic brackets produced by the channel roll forming machine are an essential component of photovoltaic power generation systems.

View more